Composite Repairs for Aircraft Parts

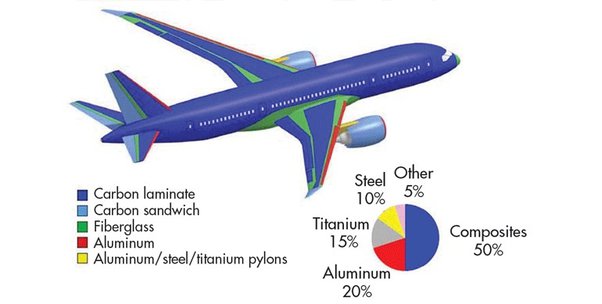

Composite materials have revolutionized the aviation industry, offering significant advantages over traditional materials. They are lighter, stronger, and more resistant to environmental factors. However, like all materials, they can become damaged and require repair. This is where the importance of composite repairs for aircraft parts comes into play.

Composite repairs are crucial in maintaining the integrity and safety of an aircraft. Damaged composites can compromise the aircraft's structural integrity, leading to potential failures. Therefore, timely and effective repairs are essential.

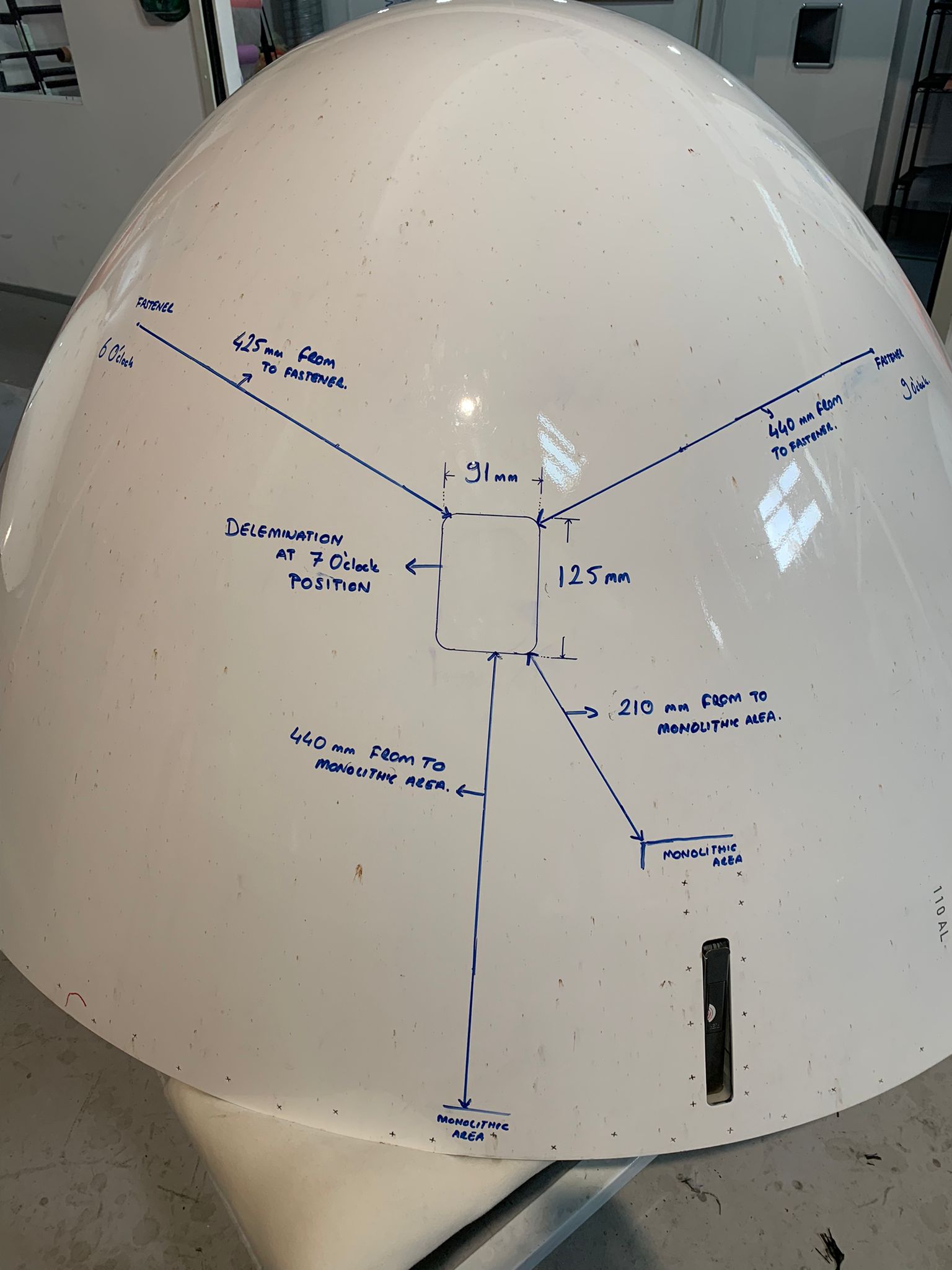

Composite materials can suffer from various types of damage, including impact damage, delamination, and environmental degradation. Each type of damage requires a specific repair process to restore the part's original strength and functionality.

There are several techniques used in composite repairs, including patch repairs, scarf repairs, and bonded repairs. The choice of technique depends on the extent and type of damage, the specific composite material, and the part's function.

Patch repairs involve applying a patch of the same composite material over the damaged area. The patch is typically bonded to the original part using a high-strength adhesive.

Scarf repairs involve removing the damaged material and replacing it with new material. The repair area is tapered, or 'scarfed,' to provide a larger bonding area for the new material.

Bonded repairs involve using a high-strength adhesive to bond the repair material to the original part. This technique is often used for minor damage and can be performed quickly and efficiently.

In conclusion, composite repairs play a vital role in maintaining the safety and performance of modern aircraft. With the increasing use of composite materials in the aviation industry, the importance of effective composite repair techniques cannot be overstated.